What is drone control board reverse engineering?

Drone control board reverse engineering is a process of reverse designing or copying the drone control board by analyzing the control system and circuit board of the drone to understand its working principle, structure and design ideas.

This process usually includes detailed analysis and research on the circuit diagram, component layout, connection methods, etc. of the drone control board to obtain the working principle and function implementation of the control board, and ultimately achieve the same or similar functions.

In the reverse engineering of drone control boards, it is usually necessary to use professional reverse engineering tools and software, such as EDA tools, disassembly tools, circuit simulation software, etc., to help engineers conduct detailed analysis and simulation of the drone control board. Additionally, reverse engineering of a drone control board requires in-depth knowledge of electrical engineering and computer science, as well as a deep understanding of the drone control system.

It should be noted that reverse engineering of drone control boards involves some legal and ethical issues. When reverse engineering the drone control board, you must comply with relevant laws, regulations and ethics, and must not infringe on the intellectual property rights and interests of others. At the same time, reverse engineering also needs to be carried out under the premise of being scientific, reasonable and legal, and must not be used for illegal purposes.

What is Drone Firmware Reverse Engineering?

Drone firmware reverse engineering refers to the process of reverse analysis, research, analysis and processing of drone firmware. It includes the derivation and reproduction of design elements such as the functional characteristics, organizational structure, processing flow and technical specifications of the UAV firmware.

In the field of drones, reverse engineering can be applied in the following aspects:

- Firmware upgrade and repair: Through reverse engineering, the internal code of the drone firmware can be extracted, modified and upgraded to improve the performance of the drone or fix known firmware vulnerabilities.

- Firmware extraction: Some drones may have restricted access to firmware. Firmware files can be extracted through reverse engineering for further analysis and operation.

- Safety analysis: Reverse engineering can also be used to analyze the safety of drones. Through in-depth reverse analysis of the firmware, possible security vulnerabilities or malicious code can be discovered, so that appropriate security measures can be taken.

- Custom firmware development: Reverse engineering can be used to develop custom drone firmware. By reverse engineering the firmware of the target drone, we can understand its internal structure and functional implementation, thereby developing custom firmware with specific functions or optimized performance.

It is important to note that reverse engineering is a complex and technically demanding task that requires deep software knowledge and an in-depth understanding of drone technology. At the same time, when performing reverse engineering, you should abide by laws, regulations and ethical principles, and must not infringe the intellectual property rights of others and conduct illegal activities. Drone firmware reverse engineering refers to the process of reverse analysis, research, analysis and processing of drone firmware. It includes the derivation and reproduction of design elements such as the functional characteristics, organizational structure, processing flow and technical specifications of the UAV firmware.

In the field of drones, reverse engineering can be applied in the following aspects:

- Firmware upgrade and repair: Through reverse engineering, the internal code of the drone firmware can be extracted, modified and upgraded to improve the performance of the drone or fix known firmware vulnerabilities.

- Firmware extraction: Some drones may have restricted access to firmware. Firmware files can be extracted through reverse engineering for further analysis and operation.

- Safety analysis: Reverse engineering can also be used to analyze the safety of drones. Through in-depth reverse analysis of the firmware, possible security vulnerabilities or malicious code can be discovered, so that appropriate security measures can be taken.

- Custom firmware development: Reverse engineering can be used to develop custom drone firmware. By reverse engineering the firmware of the target drone, we can understand its internal structure and functional implementation, thereby developing custom firmware with specific functions or optimized performance.

It is important to note that reverse engineering is a complex and technically demanding task that requires deep software knowledge and an in-depth understanding of drone technology.

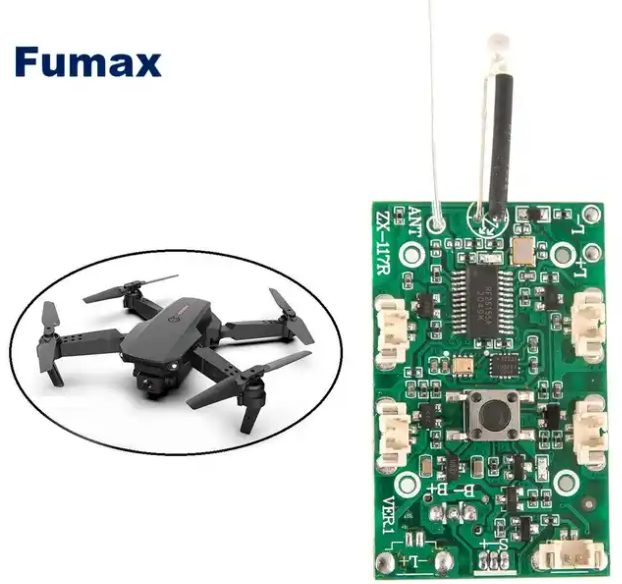

Drone control board PCB copy factory

The UAV control board PCB copying factory is an organization that specializes in UAV control board PCB copying services. These factories usually have professional board copying equipment and board copying technicians, and can provide a series of services from circuit board copying, schematic drawing, BOM table production to production debugging.

In the drone control board PCB copying factory, copying technicians usually use professional EDA software to conduct reverse engineering analysis of the circuit board of the drone control board, and scan and image the circuit board through the software to obtain Circuit board component layout, connection methods and other information. Then based on this information, board copying technicians will draw the circuit schematic diagram and BOM table, and through debugging and testing, finally produce a drone control board that is the same or similar to the original circuit board.

The service scope of the drone control board PCB copy factory includes PCB copying, schematic drawing, and BOM table production for various drone control boards, receivers, transmitters and other electronic equipment. These services can help drone manufacturers quickly obtain the core technical information of drones and quickly develop drone control boards that meet their own needs, thus accelerating the product development process.

It should be noted that the services of the drone control board PCB copying factory involve some legal and ethical issues. When performing drone control board copying services, you must abide by relevant laws, regulations and ethics, and must not infringe on the intellectual property rights and interests of others. At the same time, board copying services also need to be carried out under the premise of science, reasonableness and legality, and must not be used for illegal purposes.

What issues should be paid attention to when assembling the PCB of the drone control board?

The following issues need to be paid attention to when assembling the drone control board PCB:

- Component quality: The quality of components assembled on the drone control board PCB directly affects the performance and safety of the drone. Therefore, when selecting components, you need to choose brands and models with reliable quality and stable performance.

- Assembly process: UAV control board PCB assembly needs to follow certain processes and standards. During the assembly process, attention needs to be paid to welding quality, cable connections, component layout and other issues to ensure that every link meets process requirements.

- Debugging and testing: After the drone control board PCB is assembled, debugging and testing need to be carried out to ensure that the circuit board is working properly and that all indicators meet the requirements. This includes testing the circuit board’s power supply, signals, interfaces, etc., as well as flight testing.

- Quality control: During the assembly process of the drone control board PCB, a strict quality control system needs to be established to ensure that the quality of each link meets the requirements. This includes inspection of components, monitoring of the assembly process, debugging and recording of test results, etc.

- Safety: Safety issues need to be considered when assembling the drone control board PCB. During the assembly process, care needs to be taken to avoid dangerous situations such as short circuits and overcurrents to ensure the safety and stability of the drone.

In short, UAV control board PCB assembly requires attention to many aspects, including component quality, assembly process, debugging and testing, quality control and safety, etc. Only by comprehensively considering and strictly controlling every link can the performance and quality of the drone be guaranteed.

Best drone PCB design manufacturer in China

The following introduces you to the 5 best drone PCB design and manufacturers in China.

- Shenzhen Fumax Technology Co., Ltd.

Shenzhen Fumax Technology Co., Ltd. specializes in circuit board PCBA design and customization, drone PCB board customization, drone PCB reverse engineering, software programming, component procurement, DIP welding, assembly testing and painting, etc. Stop service.

Fuamx is a professional drone PCB board foundry that provides a full range of design, manufacturing and testing services and can be customized according to customer needs.

Customized HDI PCB board, FPC flexible circuit board, aluminum substrate, phenolic PCB paper substrate, composite PCB substrate, glass fiber PCB substrate and other special PCB circuit board customization.

- Shenzhen Hengchenghe Electronic Technology Co., Ltd.

Shenzhen Hengchenghe Electronic Technology Co., Ltd. is a company specializing in the design and production of drone PCB boards. It has many years of industry experience and a professional technical team.

The company’s PCB board foundry services include design, manufacturing and testing. In terms of PCB board design, Hengchenghe Electronics uses advanced EDA design software to achieve high-precision PCB board design and ensure the reliability and stability of the design. In terms of manufacturing, the company has advanced PCB board production lines and first-class manufacturing processes, which can guarantee the manufacturing quality and delivery time of PCB boards. In terms of testing, Hengchenghe Electronics uses professional testing equipment and testing procedures to conduct comprehensive tests on PCB boards to ensure that their quality and performance meet the requirements.

In addition, we also provide customization services for drone PCB boards, which can be customized according to customer needs and requirements, including PCB board size, number of layers, materials, processes, etc. The company also provides a series of additional services, such as PCB board welding services, drone assembly services, etc., to meet the different needs of customers.

- Shenzhen Huashengxin Industrial Co., Ltd. Have excellent PCB design and manufacturing capabilities. Provide a full range of services for drone PCB board design and production.

- Beijing Tianyu Chuangtong Technology Co., Ltd. is a professional UAV system solution provider and UAV manufacturer in China that integrates aerial survey drones, UAV design, production, and integration. The UAVs are reasonably priced. .

Specializing in high-precision PCB prototyping and batch processing, FPC flexible circuit boards, aluminum substrates and other special PCB circuit board customization. Focus on PCB design and its value-added services, including SI\PI\EMC\DFM analysis and other services.

- Shenzhen Sanyou Electronic Technology Co., Ltd.

Focusing on PCB design and electronic manufacturing services, we provide customers with one-stop services from PCB design to PCBA production.

These companies have excellent performance and professional technical capabilities in the field of drone PCB design and manufacturing.