Electronic manufacturing service refers to the process of designing, producing, testing, and assembling electronic devices and systems. This process involves a wide range of activities, including designing circuits and components, sourcing materials and components, assembling and soldering components onto printed circuit boards (PCBs), testing and verifying the functionality of the finished product, packaging and shipping.

Now, put on anti-static suit and let’s have a look!

PCBA, first step in Electronic Manufacturing Service:

PCB Fabrication

PCB(Printed circuit board),as the basic carrier of electronic devices, its function is to carry the current and allow it to pass through the designated place. So you’ll see blueprints of it, usually in Gerber format, with lots of dense lines. Circuit boards are usually made of insulating materials like epoxy and conductive materials like copper layered on top of each other, and your Gerber file will show you how they are stacked.

Suppliers will produce specific boards based on your blueprints and specifications. Every Fumax circuit board is tested before putting into production. Sometimes, we even design a specific test jig for a particular project to test the function of the circuit board, below are jigs built by us. For more, click here to know Fumax PCB capabilities!

EMS Procurement

At the same time, the sourcing team will star inquiring to components vendors.

Usually, a BOM contains dozens or even hundreds of different types of components. which even involves structural parts (including enclosure), cables and display screens, etc. Our team will classify them and make inquiries to multiple suppliers for each category to get the best offer combination based on your plan.

We have a very strong sourcing & purchasing team which maintain great relationship with more than 300 vendors.

Strictly according to customer Bill of Materials (BOM), unless specified, all components we sourced are original components with great quality.If there are substitute parts needed (for great cost reduction or shorter lead time), Fumax will notify customer first and provide datasheet or sample testing results for customer approval. We will not use the substitute parts unless customer’s written approval.

Our materials team are focus on:

•Cost effective Materials solutions

•New Supplier Qualification Process

•Regularly supplier performance survey system

•RoHs materials compliance

•Cost Saving Method

•Quarterly quality review

•More than 300 vendors

•More than 10000 kinds of component

Pcb Assembly

Now, we have all the components and PCB, once they’re quality checked, we could start assembling! Click here to know detailed Fumax PCB assembly capabilities!

PCB assembly is the process of attaching electronic components to a printed circuit board (PCB) to create an electronic circuit. The process involves placing the components onto the PCB in their correct positions, soldering them in place, and testing the assembled PCB to ensure that it is functioning properly.

There are several different methods for assembling PCBs, including surface mount technology (SMT), and through-hole technology (THT).

The PCB assembly process begins with cleaning and applying solder paste to the pads. Components are placed on the PCB with a pick and place machine. A re-flow oven melts the solder paste and solders the components onto the PCB

After soldering, PCBs undergo inspection for proper component placement and soldering. This step ensures quality control. Any defects are corrected, and the PCB is tested to ensure that it is functioning correctly.

PCB assembly is a critical step in electronic device manufacturing. It requires precision and attention to detail. Mistakes can result in faulty devices.

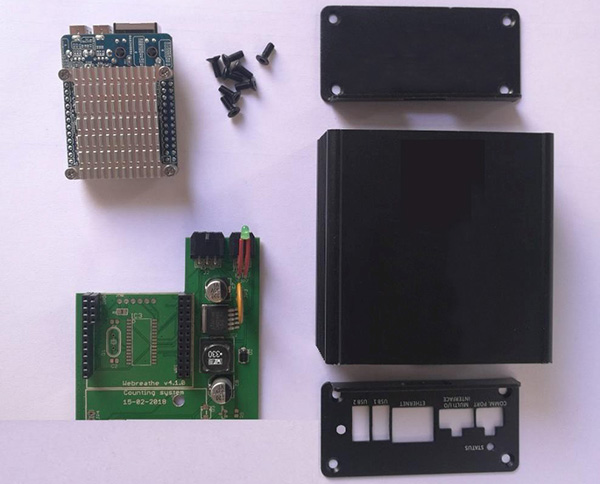

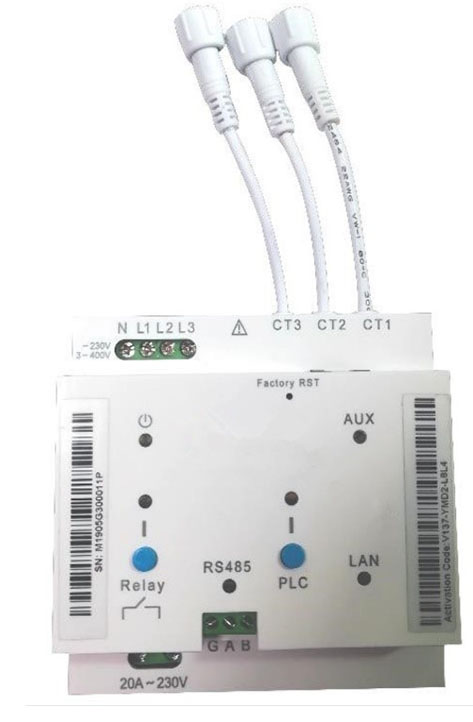

Enclosures and Finished Assembly, second step in Electronic Manufacturing Service

Box building and finished product assembly

Enclosures play a crucial role in the design and functionality of electronic devices. They provide physical protection for electronic components, preventing damage from moisture, dust, and impact. They also enhance product aesthetics, with a variety of shapes, sizes, and colors available to match device design.

PCBA enclosures come in two main types: metal and plastic. Metal enclosures provide a higher degree of protection and durability, while plastic enclosures are lighter and more cost-effective. After PCBA production, the enclosures are assembled through a variety of methods, including screws, snap-fit mechanisms, or adhesives. By securely housing the PCBA within its enclosure, external factors are prevented from affecting its performance, ensuring optimal functionality.

Electronic product enclosures are vital for device safety, performance, and appearance. Fumax offers box building services, so you don’t need another supplier!

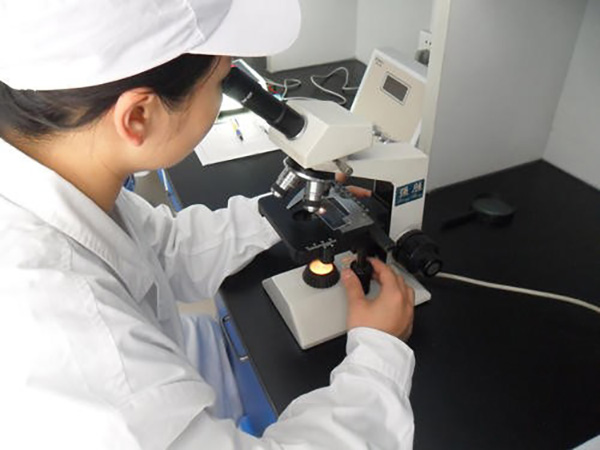

Functional Testing

As products are finished, now we can proceed the most critical step before shipping: functional test(FCT). This step is necessary to ensure that the shipped product is 100% working properly. Customized test jigs are used to mass test PCBA functionality after burning, following customer test procedures. This helps ensure proper functionality and reliability of the electronic products. Discover how Fumax Technology’s one-stop turnkey electronic manufacturing services can optimize your production process and deliver high-quality products

Packaging

Good packing will protect the products from being damaged during long distance transportation. In addition to the most basic anti-static bubble film, we also provide anti-static bags, custom insert, and custom color packaging. You can sell the goods immediately after receiving them!

Summary

The production processes of electronic manufacturing has a high requirement for the environment and technology level. Choosing professional and reliable suppliers is crucial in the electronic manufacturing industry due to the complex and specialized processes involved. Fumax Technology has been providing customers with one-stop turnkey electronic manufacturing services for decades, making us a trustworthy partner in the global market. Discover how we can help you streamline your supply chain and deliver high-quality products with our reliable and efficient services.