LED display board assembly is a process involving multiple steps and details, and needs to be carried out in strict accordance with operating specifications to ensure product quality and stability.

The following is a detailed introduction to the assembly of LED display boards for your reference:

Incoming material inspection

- Check each component of the LED display to ensure there is no obvious damage or defect;

- Check the specifications, models and quantities of all components to ensure they are consistent with the design requirements;

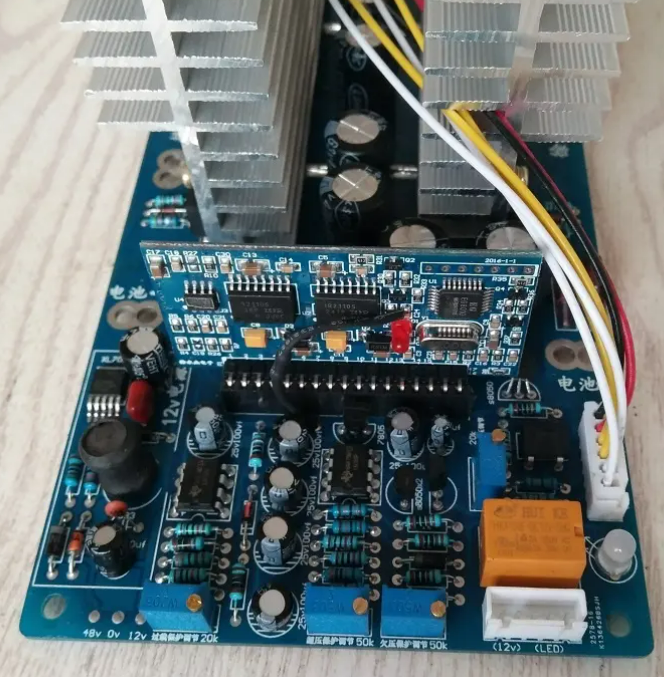

- Conduct a visual inspection of the PCB board to ensure there is no damage or poor welding.

SMT

- Place the SMT components in the corresponding positions according to the marked positions on the PCB;

- Use an SMT placement machine or manually place components such as ICs, resistors, capacitors, etc. on the PCB;

- Ensure that the components are placed accurately and there is no obvious offset or skew;

- Check the PCB after placement to ensure that no components are missing or placed incorrectly.

Welding

- Use appropriate welding techniques (such as hot air welding, soldering iron welding, etc.) to firmly weld the components on the PCB;

- Ensure that the welding quality is good and there are no weak welds, missing welds, etc.;

- Check the PCB after welding to ensure that the welding quality meets the requirements.

Debugging and testing

- Conduct functional testing on the assembled PCB to ensure that the display module, control module and other parts are working properly;

- Adjust the brightness, color temperature, contrast and other parameters of the display screen to meet customer needs;

- Check the display effect of the display to ensure that there are no obvious color distortion, uneven brightness, etc.

Aging test

- Connect the display to the power supply and control system and conduct a long-term aging test;

- During the aging test, observe whether there are any abnormal phenomena on the display screen, such as color distortion, uneven brightness, etc.;

- For abnormal display screens, handle and repair them in a timely manner.

Packaging and shipping

- Use appropriate materials and methods to package the display to prevent damage during transportation;

- Before packaging, make sure the display is completely dry without any moisture or residue;

- Place shock-absorbing materials inside the packaging box to reduce vibration and impact during transportation;

- Mark the warning signs and fragile items signs on the packaging boxes to ensure safe transportation.

Precautions

- During the assembly process, keep it clean to avoid the mixing of dust and impurities;

- For some sensitive components, such as ICs, sensors, etc., special care must be taken to avoid damage or contamination;

- During the welding process, the temperature and time must be controlled to avoid damage to components and PCB;

- During the debugging and testing process, pay attention to safety to avoid damage to circuit boards and components or personal injury;

- During the burn-in test, continue to pay attention to the status of the display screen, and discover and deal with problems in a timely manner.

The above is the basic process and precautions for LED display panel assembly. In actual operation, it also needs to be adjusted and processed according to specific conditions.

At the same time, in order to improve the efficiency and quality of assembly, it is recommended to use automated equipment and professional technicians to operate.

LED display board assembly company

Fumax Company is a manufacturer specializing in LED display board assembly, with advanced production equipment and a professional technical team. The company is committed to providing customers with high-quality, high-efficiency LED display board assembly services to ensure product reliability and stability. With many years of industry experience, Fumax has become one of the most trusted brands in the industry.